XL Flex Arms, posable mounting for cameras and lighting.

I’ve been working on my setup in the studio for a bit, and one thing I consistently need is better lighting. A while back I’d purchased a few cheap photography light panels that I’d mounted on lamp arms. Unfortunately those would no longer work in my current setup due to the setback from any sort of mounting. So after carousing YouTube for memes I came across one of Adam Savage’s One Day Build videos, where he uses large Loc-Line to build a few mounting arms for the lights used in his videos.

And I was inspired.

Posable light where you need it is so important for working on detailed projects, especially if you’re trying to get better at documenting the work you’re doing while you’re doing it. With that inspiration I started looking into the cost of doing some of this. The first issue I ran into was that I didn’t have any of the 3/4” Loc-Line laying around. A quick search returned that the going rate is about $60 for a 10ft length. While not outrageous, I do have a machine that is quite capable of forming plastic into just about any shape I want, so I got to work on making my own.

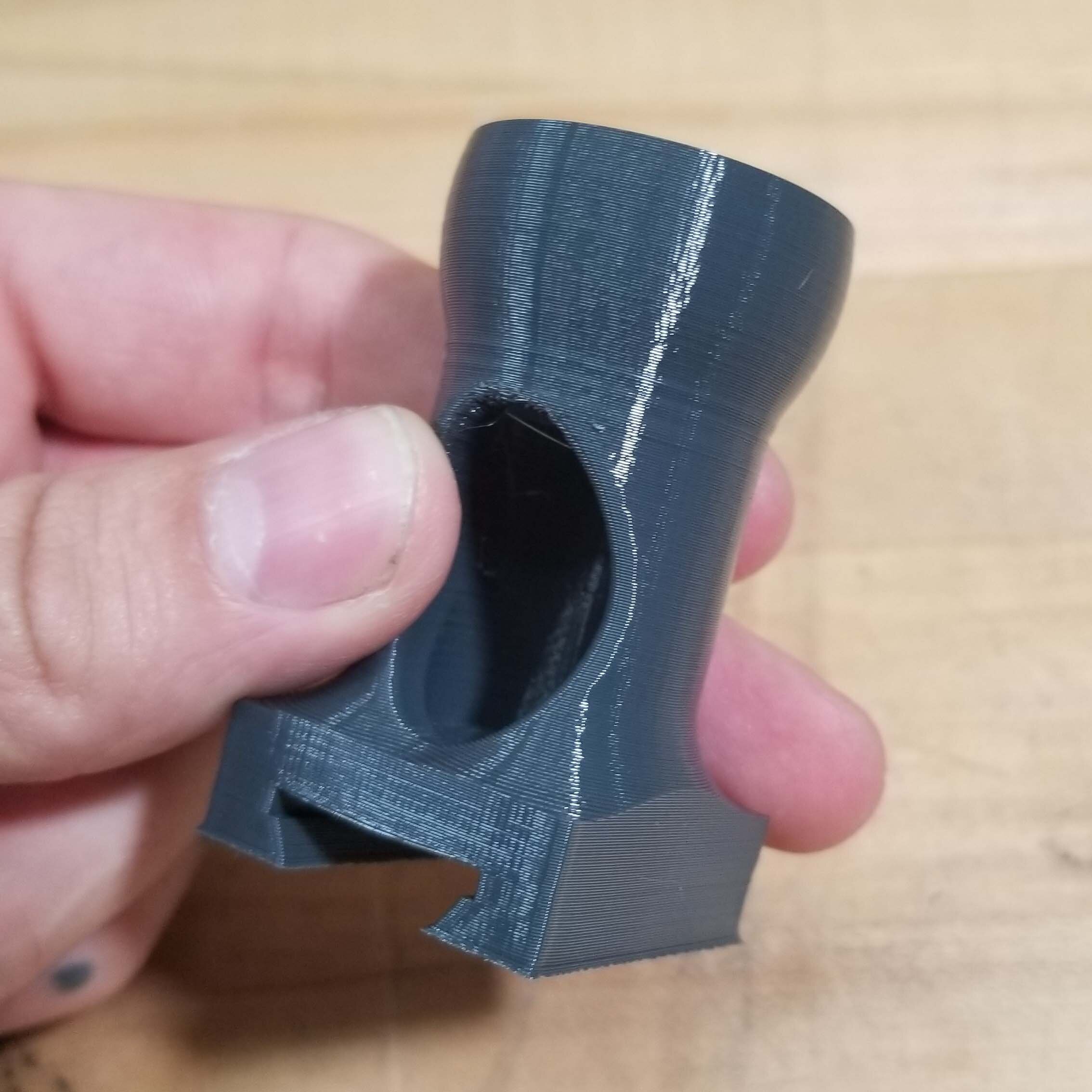

First pass online returned that there were indeed folks thinking the same thing, and that there were existing models ready to be modified. This model by Thingiverse user charlespax served as the basis for my revision. I scaled up the model to twice its size, but in doing so threw off some of the tolerances of the interfacing cups - Version 1. I changed a few of those tolerances and extended the neck - Version 2. Turns out that change on the diameter of the mating parts was too tight, and so I modified it again to get a version that mated snugly but pliable - Version 3.

The version (v3) I ended up is about 60mm long with just under 2-3/8") with an internal diameter of 16mm (just over 1/2"), and only uses perimeters in printing which drastically speeds the printing process.

I was printing in PETG (Specifically Atomic Filaments’ Grey PETG PRO, which is great) at 0.2mm layers using my Prusa i3 MK3. After dialing print settings in a bit I was able to print 30 at a time…

Total print stats came to just over 24 hours print time, 5ft assembled length, and about 255g of filament.

At $32 a kg for the pro PETG, 255g translates to $8.16 in materials, which means the price of printed myself (excluding machine time) came to about $1.63 a foot, which is pretty good compared to the $6 a foot of 3/4 Loc-Line. Which I’d say is pretty good.

Assembly ended up being a bit tricky though, they fit together pretty snugly. I had to apply quite a bit of force to push them together, and found the trick was to push them together at a slight angle and use my thighs to apply enough force to force them together. In addition I ended up having to debur the edges printed against the bed of the printer as they became very sharp. Even after that, I still wore work gloves to assemble.

Not quite watertight, but close. It drips a bit at extreme bends of the pipe.

A this point I tested whether the tube could support a 2-3 lbs payload on its own, which failed pretty handily with a 5ft arm. So, following the tutorial I purchased some armature wire from a friend and decided to test that. I used 3/16” stainless steel wire for my tests.

Form there I needed to make mounting for the bits and bobs that would be attached to either end of the arm. First was a flat mount with screw holds for mounting to the table, second was a camera shoe for mounting the light panel. For the flat mount I incorporated a tunnel to route the armature wire to capture it underneath the mount, and threw in a pass through for zip ties to secure any wires that would run inside the pipe. For the camera shoe, I made it to fit a standard 1/4-20 bolt to secure camera equipment down with.

Boom, cool.

But not quite that easy.

I did a test fit of the full length arm with the base screwed down and with the wire inside, and there was enough leverage at the base to snap the thin neck of the mount when I was posing the arm. Stuck between a slightly pliable but long arm and a very heavy desk, the thinner plastic of the mount didn’t stand a chance as a fulcrum. I revised the mount to have a much longer neck and added in some support buttresses.

I screwed it in with a few 3/4” #8 flat heads and threaded through the power wire… Speaking of….

Nothing fancy, just a 12v 5a DC adapter fed to a Y-Split, with a couple of 10ft barrel jack extension cables that feed the LED panels. What wire isn’t inside the arms will be secured to the underside of my desk with sticky backed zip tie mounts.

Nice.

I printed out 2 and they now live on either far edge of my work desk. All told, with materials used I spent about $50 to print everything out and wire it all up, not including the light panels. I think I’ll print out a 3rd for a Go-Pro mount as well, as the over the desk time lapses turn out really well with proper lighting.

STLs of all the files here (Download- 1.25 MB) and on Thingiverse.

Cheers,

Mac